The link between battery quality and range

The energy output of batteries depends on the number of cells and the capacity of the battery along with the conditions it is being used under. The quality claimed by the battery pack manufacturers might not translate to real life performance on road. Therefore, there is always a need for accurate testing and validation to protect all parties involved.

RC Labs has always differentiated itself from the incumbent by delivering products of the highest quality through rigorous testing, optimized battery and BMS compatibility. This enables the BMS to evaluate performance using numerous cycle tests. The results show any shortcomings with the quality of the battery. One such instance a customer complained of range drop. The range was 20% less than what was expected, according to the OEM.

The BMS was able to identify a failure in the module in less than 500 microseconds . A module was shorted and a voltage readout of zero revealed the malfunction (refer Fig. 2). This is because of poor quality cells or battery pack manufacturing. There can be catastrophic implications like permanent impairment of batteries, damage to vehicles and its components, fires & explosions. The vehicle’s range is significantly impacted by the total voltage drop. The best solution for this issue is to swap out the current modules.

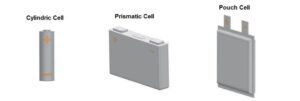

Here, the type of cells has a significant impact. Prismatic, pouch, and cylindrical are the three primary form factors (Fig. 1). While each of them have advantages and disadvantages of their own, prismatic cells are the most practical for replacing and connecting cells/modules. Fewer cells are required to produce the same amount of energy in prismatic cells compared to cylindrical cells because of their larger capacity. They also have a screw and busbar type connection as a result of which prismatic cells are easy to assemble and disassemble. This means they require fewer electrical connections for a given volume. There are lower chances of manufacturing defects, which is a significant benefit for prismatic cells.

Fig. 1 Types of cells; Image: www.maxworldpower.com

With its predictive maintenance and battery health prognosis, RC Labs’ BMS has the ability to immediately identify flaws. The technical staff perform various tests on each battery pack and ensure that the quality and performance are documented. These documents can be used to support warranty claims, serve as a reference, and help consumers compare different battery vendors. This gives the vehicle OEMs the precise battery data they need to make an informed decision.

Fig. 2: Measured voltage plots at 14 points of the battery pack